FPGA Capacitive Keyboard Synthesizer

An FPGA-Based Musical Instrument With Custom Capacitive Sensing and Digital Audio Synthesis

WHY — Motivation, Problem, and Constraints

The FPGA Capacitive Synthesizer was my final project for Digital Systems Laboratory (6.205), developed in collaboration with Adan Abu Naaj.

The motivation behind the project was to explore how capacitive sensing can enable a level of expressiveness in electronic musical instruments that is difficult to achieve with traditional buttons, keys, or potentiometers. Conventional digital synth interfaces tend to discretize interaction—notes are on or off, parameters jump between values—which limits the user's ability to make fluid, continuous gestures.

Capacitive interfaces, by contrast, naturally support continuous, gesture-based control. A performer can smoothly slide across pitches, modulate parameters in real time with finger position or pressure, and control multiple dimensions of sound simultaneously. For example, a vertical column of ribbon-shaped capacitive pads can be mapped to a single note, allowing per-note control over filters or effects while the note is held—something that is cumbersome or impossible with standard key-based interfaces.

Achieving this level of expressiveness requires scanning many capacitive sensors at high rates and mapping them to sound parameters with minimal latency. An FPGA is well-suited to this problem: it allows massively parallel sensor scanning, deterministic timing, and low-latency signal processing that would be difficult to guarantee on a microcontroller or general-purpose CPU.

The project was inspired by expressive touchscreen-based instruments such as GeoShred, with the goal of implementing similar expressive capabilities in a custom hardware instrument built around capacitive sensing and FPGA-based real-time control.

Project Constraints

Hardware Specs

- Spartan-7 FPGA

- Limited BRAM + DSP slices

Performance

- Touch → Audio latency < 10ms

- Instantaneous feel

Complexity

- Polyphonic mixing w/ arbitration

- No off-the-shelf IP cores

Sensing

- 24–36 capacitive pads

- Noisy & timing-sensitive

WHAT — System Overview

A high-level architecture view:

Hardware System Components

Capacitive Interface (My Work)

Iteration 1: Proof of Concept

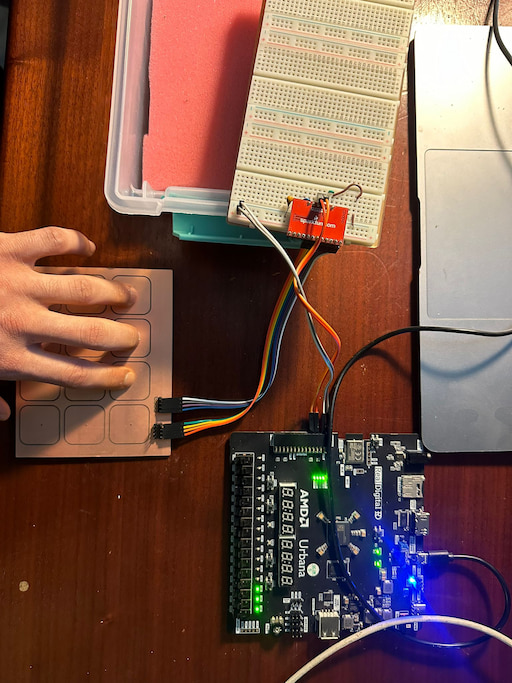

The first iteration (below) was a simple 4x3 grid used to validate our custom I2C drivers and touch sensitivity.

Iteration 2: Final Design

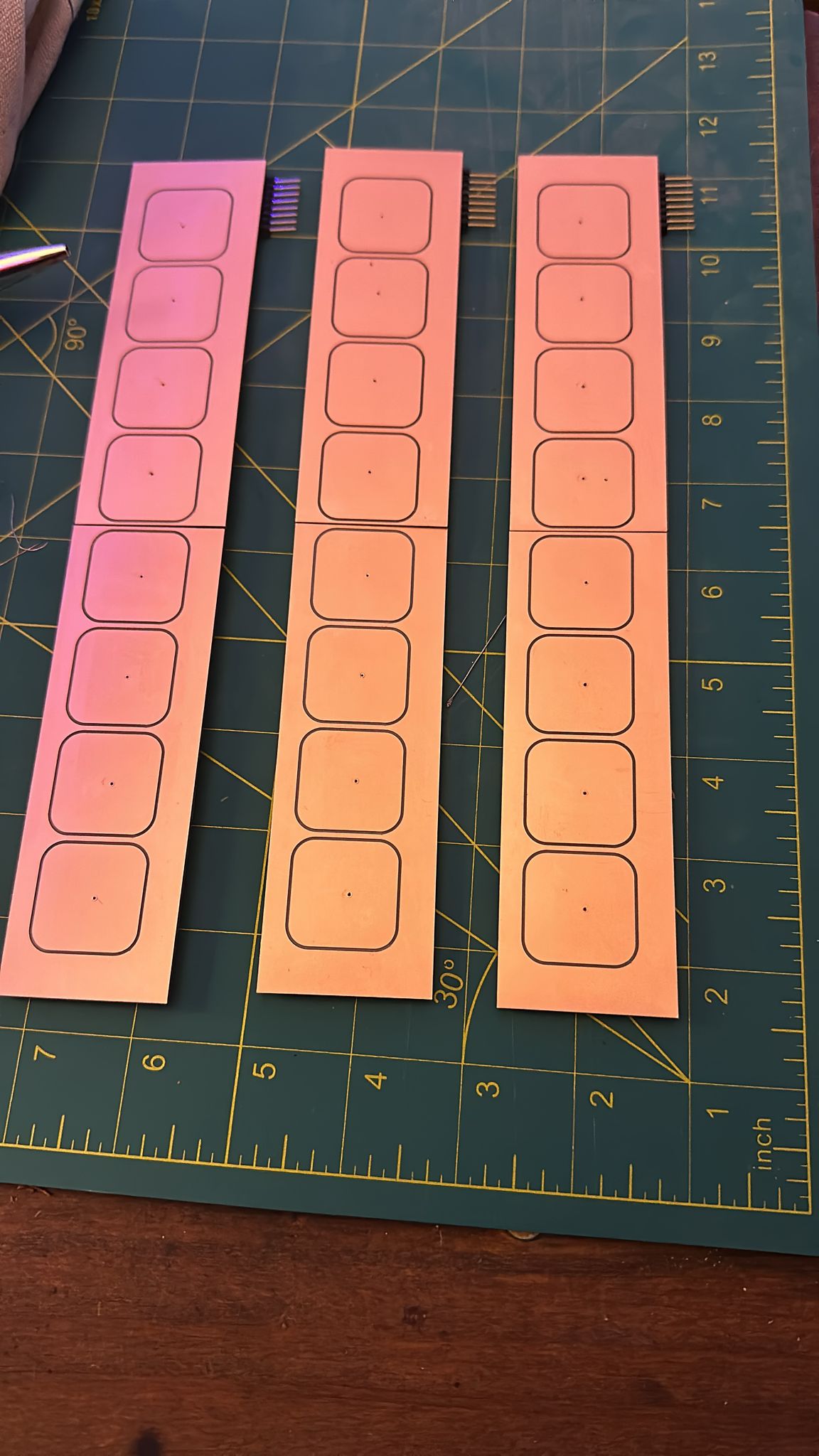

The final interface (below) consists of three separate rows of 8 capacitive pads each, designed to align perfectly with the laser-cut body.

Fabrication Constraint: We milled the PCBs on an Othermill, which has a max bed width of 140mm—too short for a full 8-pad strip.

Solution: Each 8-pad row is actually composed of two 4-pad PCBs joined on the underside with SMD horizontal headers.

- 24 copper pads total

- 3× MPR121 ICs

- Address-configured to scale to 36+ pads

- Routed via PMOD cables to FPGA board

Custom I²C Controller (My Work)

High-Stakes Hardware Debugging

Unlike authentic Adafruit boards, the knockoff MPR121 modules we sourced had a manufacturing defect where the address selection pin was hardwired to 0x5A, making multi-chip communication impossible. To fix this, I had to reverse-engineer the PCB trace and physically cut the hidden connection with an X-Acto knife under a microscope to restore address configurability.

To achieve low-latency multi-chip polling, I designed a hand-written 9-state I²C Finite State Machine rather than using a slow microcontroller bridge. This provided full control over bus timing and error recovery.

Key Challenges & Solutions

- Bidirectional SDA: Implemented precise state-driven enable/disable logic to handle the bidirectional data line without contention.

- Metastability Protection: All incoming SDA/SCL signals pass through dual-flop synchronizers.

- Bus Recovery: Added a watchdog timer to reset the FSM if the bus locks up—critical for live performance reliability.

- Repeated Start: The FSM specifically handles the "Repeated Start" condition required to read registers from the MPR121 without releasing the bus.

Below is the core state transition logic:

typedef enum logic [3:0] {

IDLE, START, ADDR, AWAIT_ACK, READ_ACK,

PROCESS_ACK, DATA, READ, STOP, BUS_FREE_TIME

} state_t;

// ...

IDLE: begin

scl_toggle_en <= 1'b0;

scl_overdrive <= 1'b1;

sda_val <= 1'b1;

data_valid_out <= 1'b0;

ack_out <= 1'b0;

if (start) begin

state <= START;

end

end

START: begin

ack_out <= 1'b0;

if (prev_byte == CMD_BYTE) begin

//repeated start

peripheral_addr_in_reg[0] <= 1'b1;

end else begin

peripheral_addr_in_reg <= {peripheral_addr_in, 1'b0};

rw_reg <= rw;

data_byte_in_reg <= data_byte_in;

command_byte_in_reg <= command_byte_in;

ack_out <= 1'b0;

end

scl_toggle_en <= 1'b1;

sda_val <= 1'b0;

bit_count <= 7;

state <= ADDR;

end

ADDR: begin

//wait for first scl toggle to 0, then start sending data on falling edge.

//each bit of data stays on the line as long as scl is high

if (scl_falling_edge) begin

sda_val <= peripheral_addr_in_reg[bit_count];

if (bit_count == 0) begin

state <= AWAIT_ACK;

prev_byte <= ADDR_BYTE;

end else begin

bit_count <= bit_count - 1;

end

end

end

AWAIT_ACK: begin

//maintain sda upto next falling edge. then set to high impedence to read sda.

if (scl_falling_edge) begin

sda_val <= 1'b1;//sets sda_out to high impedence

state <= READ_ACK;

end

end

READ_ACK: begin

//wait for scl to go high, then read sda over the clock cycles in the middle of the high period

if (half_period_count == QUARTER_PERIOD && scl_out) begin

ack_in <= sda;

state <= PROCESS_ACK;

end

end

PROCESS_ACK: begin

if ((prev_byte == DATA_BYTE) && peripheral_addr_in_reg[0]) begin

//read; end repeated start with a NACK. just need to keep sda high

state <= STOP;

end else begin

if (!ack_in)begin

//ack recieved

if (rw_reg) begin

if (prev_byte == CMD_BYTE) begin

//read; repeated start

if(scl_rising_edge) begin

state <= START;

end

end else if (peripheral_addr_in_reg[0]) begin

state <= READ;

sda_val <= 1'b1; // set to high impedence to read sda

end else begin

state <= DATA;

end

bit_count <= 7;

end else begin

if (prev_byte == DATA_BYTE) begin

state <= STOP;

end else begin

state <= DATA;

bit_count <= 7;

end

end

end else begin

//no ack recieved

state <= STOP;

retry_count <= retry_count + 1;

ack_out <= 1'b1;

end

end

end

DATA: begin

if (prev_byte == ADDR_BYTE) begin

//command byte follows if write. data byte follows if read in repeated start phase(indicated by the rw bit of the addr byte)

if (scl_falling_edge) begin

sda_val <= command_byte_in_reg[bit_count];

if (bit_count == 0) begin

state <= AWAIT_ACK;

prev_byte <= CMD_BYTE;

end else begin

bit_count <= bit_count - 1;

end

end

end else if (prev_byte == CMD_BYTE) begin

//data byte follows

if (scl_falling_edge) begin

sda_val <= data_byte_in_reg[bit_count];

if (bit_count == 0) begin

state <= AWAIT_ACK;

prev_byte <= DATA_BYTE;

end else begin

bit_count <= bit_count - 1;

end

end

end

end

READ: begin

if (scl_rising_edge) begin

data_byte_out[bit_count] <= sda;

if (bit_count == 0) begin

state <= AWAIT_ACK;

prev_byte <= DATA_BYTE;

end else begin

bit_count <= bit_count - 1;

end

end

end

STOP: begin

//ENSURE TBUF IS NOT VIOLATED

//need 0.6 ms delay before sda is pulled back high. add delay of 60 cycles between scl rising and sda rising

if (!scl_toggle_en) begin

if (stop_setup_count == STOP_SETUP_CYCLES) begin

sda_val <= 1'b1;

state <= BUS_FREE_TIME;

prev_byte <= STOP_BYTE;

stop_setup_count <= 0;

end else begin

stop_setup_count <= stop_setup_count + 1;

end

end else if (scl_falling_edge) begin

sda_val <= 1'b0;

end else if (scl_rising_edge) begin

scl_toggle_en <= 1'b0;

stop_setup_count <= 0;

end

end

BUS_FREE_TIME: begin

//wait for 1.3 ms before next start condition

if (stop_setup_count == BUS_FREE_CYCLES) begin

if (!ack_out) begin

data_valid_out <= 1'b1;

state <= IDLE;

retry_count <= 0;

end else begin

//retry

if (retry_count == 4'd10) begin

state <= IDLE;

retry_count <= 0;

ack_out <= 1'b0;

end else begin

state <= START;

retry_count <= retry_count + 1;

end

end

stop_setup_count <= 0;

end else begin

stop_setup_count <= stop_setup_count + 1;

end

end

endcase

// ...

This custom driver polls the MPR121 electrode-status registers (0x00–0x01) and exposes a clean 24-bit touch vector to the rest of the system.

This custom driver polls the MPR121 electrode-status registers (0x00–0x01) and exposes a clean 24-bit touch vector to the rest of the system.

.png)

I2C Read Format

.png)

I2C Write Format

MPR121 Driver Module(My Work)

Implements:

- Runtime configuration of thresholds

- Continuous electrode polling

- Combined 24-bit touch vector output

- Integration with interrupt-based updates

Note Decoder & Voice Allocation (My Work)

To keep the system modular, I separated gesture detection (touch processing) from voice triggering (synthesis).

- Input: 24-bit touch vector from I2C driver.

- Logic: Decodes raw capacitance into "Note On/Off" events.

- Output: Gate signals sent to the Polyphony Manager.

Digital Audio Synthesis

Two parallel sound-generation pipelines were implemented to compare synthesis techniques:

A. Procedural Synthesis (My Work)

The primary engine used Direct Digital Synthesis (DDS) with a 32-bit Phase Accumulator.

- Precision: 32-bit accumulator running at master clock allows extremely fine pitch control (smooth sliding).

- Formula:

phase_increment = (frequency * 2^32) / Fs - Waveforms: Top bits address a BRAM Look-Up Table (LUT) for Sine, Sawtooth, or Square waves.

B. Oud Sample Playback (Adan's Work)

To mimic a real Oud, we implemented a sample-based pipeline.

- Workflow: Recorded Audio → Python (Librosa) for trimming/normalization → 16kHz Downsampling →

.memfiles. - BRAM Layout: Used 4 cascaded BRAM blocks per note to store ~8k samples.

Design Pivot

While the sample playback worked, we found that improving realism became a software problem (better Python preprocessing) rather than a hardware problem. To maximize our FPGA learning outcomes, we deprioritized the sampler in the final build and focused on enhancing the Procedural Synthesis engine's real-time modulation features.

ADSR (Adan's Work)

- FSMD structure

- Attack → Decay → Sustain → Release

- Smooth multiplier applied to waveform sample

- One ADSR per voice → enables polyphony

Polyphony Architecture & Mixing (Shared Work)

The system supports 8 simultaneous voices. Managing this on a Spartan-7 required careful resource sharing:

- Challenge: Summing 8 voices blindly would cause integer overflow and digital clipping.

- Solution: A Pipelined Summation Tree with Dynamic Normalization.

The mixer monitors the number of active voices and bit-shifts the output to maintain a constant volume level, whether 1 or 8 notes are playing. This avoids expensive division operations.

// Dynamic Normalization logic to prevent clipping

case(note_count)

4'd1: multiplied_sum <= sum * 255; // Scale to maintain volume

4'd2: multiplied_sum <= sum * 128; // ~ 1/2 gain

4'd3: multiplied_sum <= sum * 85; // ~ 1/3 gain

// ...

4'd8: multiplied_sum <= sum * 32; // ~ 1/8 gain

default: multiplied_sum <= 0;

endcase

PDM Output Stage (My Work)

We chose Pulse Density Modulation (PDM) over PWM for the final audio output.

- Why? PDM pushes quantization noise into higher frequencies (noise shaping), which are easily removed by a simple analog RC low-pass filter, resulting in much cleaner audio than PWM at the same clock capability.

I implemented a First-Order Delta-Sigma Modulator to generate the PDM signal:

// Accumulator for PDM modulation (Delta-Sigma approach)

logic [PDM_RESOLUTION_WIDTH:0] accumulator;

logic [PDM_RESOLUTION_WIDTH:0] pdm_res_minus_dc;

assign pdm_res_minus_dc = PDM_RESOLUTION - dc_in;

always_ff @(posedge clk_in or posedge rst_in) begin

if (rst_in) begin

accumulator <= 0;

sig_out <= 0;

end else begin

if (|gate_in) begin

// If error (accumulator) exceeds threshold, pulse high and subtract reduction

if (accumulator >= pdm_res_minus_dc) begin

sig_out <= 1;

accumulator <= accumulator - pdm_res_minus_dc;

end else begin

// Otherwise, keep low and accumulate error

sig_out <= 0;

accumulator <= accumulator + dc_in;

end

end else begin

sig_out <= 0;

end

end

end

Enclosure & Fabrication (Adan's Work)

The body was laser-cut from plywood, designed to hide all wiring while keeping the capacitive pads accessible for playing.